Turbine Blades

Aerospace

In Aviation manufacture industry almost 75% of the engine components, turbine blades and moving components are coated with some kind of protective barrier to ensure maximum performance in the lowest weight ratio. The primary functions of thermal spray coatings in the aero industry are thermal barriers, high temperature corrosion resistance, abradable and high wear resistance at high temperatures. Shafel Tech is supplying coatings for Hindustan Aeronautical Ltd., Bangalore since 2000.

Components

-

-

Combustion Vanes

-

Turbine Vanes

-

Landing Gear Components

-

Closing Pistons

-

Support Bearings

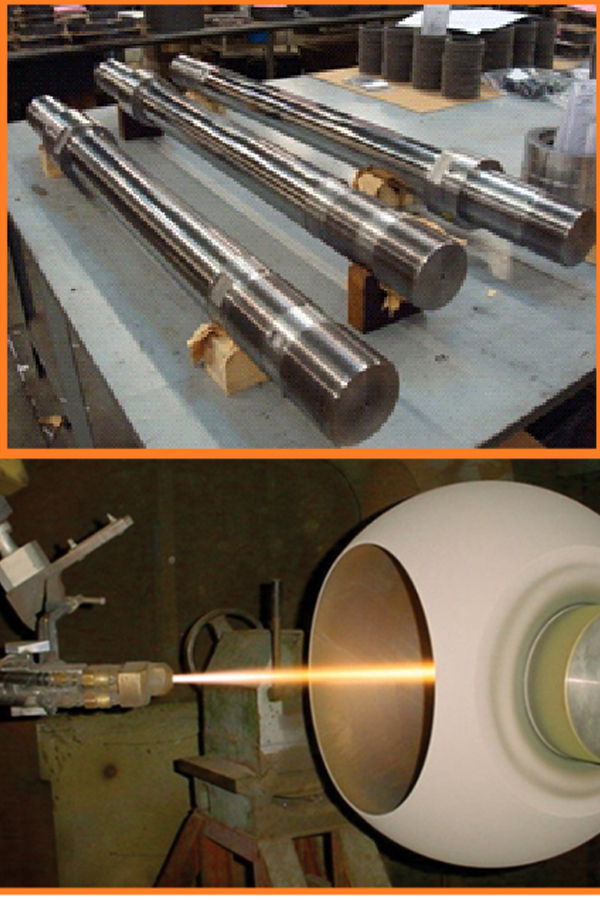

Steel

Steel Industry equipment is subjected to extreme conditions of heat, cyclic shock, metal friction, corrosive atmosphere and above all severe wear in a relatively short period of time. Hence Steel Industry equipment and handling machinery requires excellent surface protection characteristics not only to withstand the extreme conditions but also to give sufficient life to make the process of steel making cost effective.

Components

-

Bridle Rolls

-

Deflector Rolls

-

Run Out Table Mill Rolls

-

Gripping & Guiding Rolls

-

Looper Rolls

-

Furnace Rolls

-

Zinc bath Rolls and many more rolls

-

Sleeves & Shafts

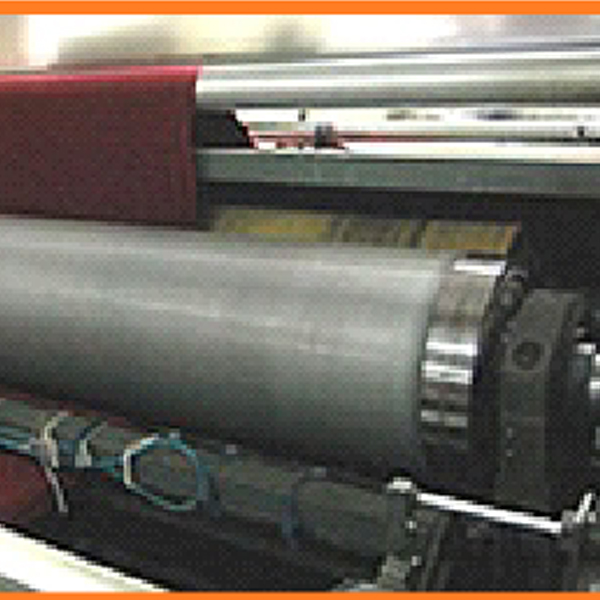

Paper & Print Industry

Today's machinery used in Paper & print Industry process very high speed production. The rollers used in the machinery are subjected to severe wear & corrosion by ink and other particles. The gripping of paper is subjected to severe wear and the gripper looses it gripness, hence high strength coatings are required to withstand erosive wear but maintain roughness. Other rollers require low coefficient of friction and to prevent wet paper, adhesives, ink from sticking to rolls surface.

Components

-

Calendar Rolls

-

Ink pick-up 5 start thread rollers

-

Printing Rolls

-

Plate cylinders

-

Guide Rolls, Suction Rolls

-

Grippers and grip rollers

-

Coiling Rolls

-

Corrugated Rolls etc

Oil & Gas Industry

Components in this industry are subjected and exposed to sever wear, heat & corrosion. Many parts are coated with Thermal spray coating to act as excellent high hardness & high toughness barrier to these conditions. Primarily piston rods, shafts & sleeves when worn out by a few hundred microns will lose its applicability in this industry.

Components

-

Gas Compressor Piston Rods

-

Seal Rings

-

Sleeves & Plungers

-

Ball Valves

-

Mud Pump shafts

-

Wear Rings

-

Slush Pump Piston Rods

-

Wear Rings, Gate Valves etc.

Power Generation

In Thermal Power industries there are various moving parts subjected to high heat, corrosion and wear. Hard surface thermal spray coatings act as an excellent barrier to save from material degradation and thus enhance life.

Components

-

Guide Vanes

-

Slurry Pump Sleeves

-

Pump Shafts

-

Guide Vanes

-

Turbine Blades

-

Valve Spindles

-

Valve Cones

Wire & Cable Industry

The high hardness wires when subjected to drawing or size reduction will cause the tools which are instrumental in their production like wire drawing drums and pulleys subjected to severe sliding wear and cutting load on the surface. Hence these surfaces have to be protected from high sliding wear resistance. Normal hardened metallic surfaces cannot withstand the stress & cutting wear of the high speed wires over even for a short period of time, hence hard face coatings acts as an excellent barrier for wear and thus enhance life and tool productivity.

Components

-

Step Cone Pulleys

-

Wire Drawing Drums

-

Guide Rollers & Guide Pulleys

-

Wire drawing Rings

-

Dancer Pulleys

-

Diversion Pulleys etc

Textile Industry

Very fine cutting wear is pronounced in the Textile Industry as kilometers of fibrous material pass though metallic components. The components should have very low coefficient of friction to prevent easy flow of fibers and prevent breakages. Compaction Rollers in Fabric (100% cotton knitted fabric) compaction and shrinkage / pressing of fabric in lengthwise direction. Open width and tubular compacting machines use coated rollers.

Components

-

Compaction Rollers

-

Godet & Draw Rolls

-

Separate Rolls

-

Finish Applicators

-

Thread Guides

-

Rotary

-

Storage & Friction Disks

Automotive Industry

For heavy duty vehicles and for vehicles used in highly abrasive atmosphere thermal spray coatings act as an excellent wear resistant barrier for longer life and performance enhancement at high speeds and heavy load conditions.

Components

-

Worm Shafts

-

Piston Shafts

-

Piston Rings

-

Aluminium Alloy Wheel Flange Hub

-

Connecting Rod

-

Cam Shaft Etc

Pump & Valve Industry

Various sleeves and shafts and the pump used in slurry conditions are subjected to high erosive wear and cannot withstand the conditions even for a few months. These components are thermal spray coated to extend life and withstand the application. Rotary air lock Valves used in abrasive media require very hard uniform coatings to maintain the air gap in the valve for effective function (prevent leak)

Components

-

Slurry Pump Sleeves And Pump Housing

-

Rotary Airlock Valve Systems

-

Sleeves And Shafts In Abrasive And Corrosive Applications.

Petrochemical & Pharma Industry

Chemical corrosion acts as a main impediment for components used in this industry. Various components manufactured with highly alloyed materials are expensive for these applications and hence thermally coated high corrosion resistant coating seems as a potential alternative for cost cutting and life enhancement.

Components

-

Sleeves & shafts (other rotating parts) used in corrosive atmosphere, piston rods etc

Abrasive Manufacturing Industry

The abrasive sieves manufacturing industry use impellers for exiting the abrasive materials after crushing and these impellers vanes are subjected to severe wear. Thermally sprayed hard coating (even over mild steel) enhances the performance & the life of impeller and result in huge cost savings.

Components

-

Impellers and shafts.